Wall elements

According to function

- Interior elements

- Exterior elements

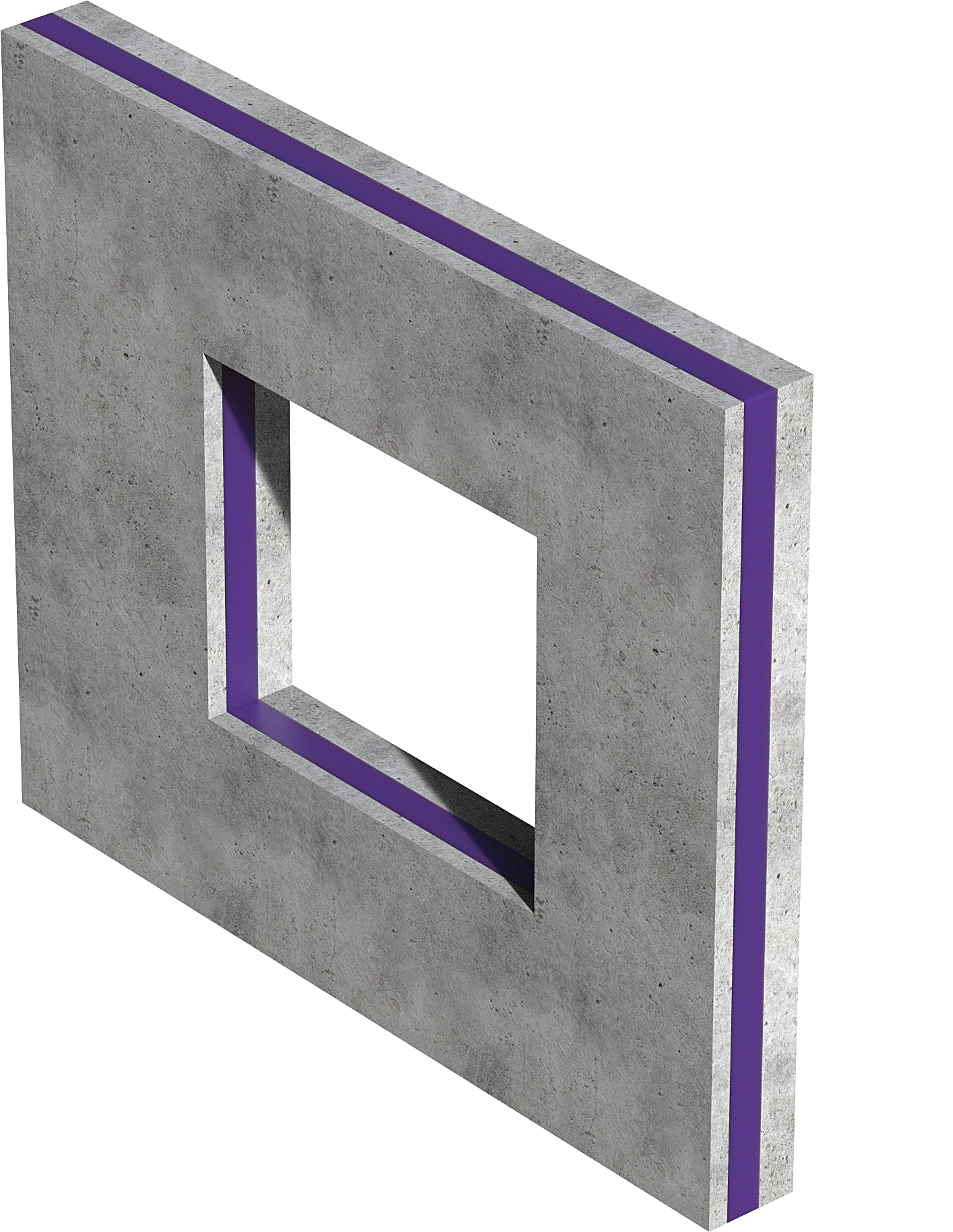

Sandwich elements

Sandwich wall elements comprise a load bearing interior layer (thickness of the layer depends on the loads), exterior layer (usually 70–90 mm) and insulating material (glass or rock wool, polystyrene foam) installed between the two. Wiring ducts for electric, communications, etc. cables may be installed inside the wall elements.

Using sandwich elements has several advantages – among others, the speed of assembling the building, accuracy of dimensions of elements manufactured in the factory and wide selection of exterior finishes, sound-proofing and thermal insulation indicators complying with standards, fire integrity, ability to carry out construction work during the cold season.

Single-layer elements

Single-layer elements can be interior or exterior walls, load bearing or non loadbearing wall. Single-walls can also be acting as beam elements

Finishing solutions

- Power trolled

- Brushed

- Raked

- Tiled

- Painted

- Patinated

- Pigmented

- Washed

- Graphic design

- Textured

- Rolled

Quality

Wall elements are manufactured according to the requirements of the standard EVS-EN 14992 Precast concrete products – Wall elements and EVS-EN 13369 Common rules for precast concrete products.